SPYRE cleaning lasers made by LASCAM are designed and manufactured to meet the needs of our customers as well as the highest standards for processing quality and safety. They are suitable for application in continuous production in industry.

Applications

Paint shop maintenance

Weld preparation and treatment

Industry

01

Plastics Industry

Cleaning injection and foaming moulds and their peripherals to remove grease, operating impurities, or pressure rust.

02

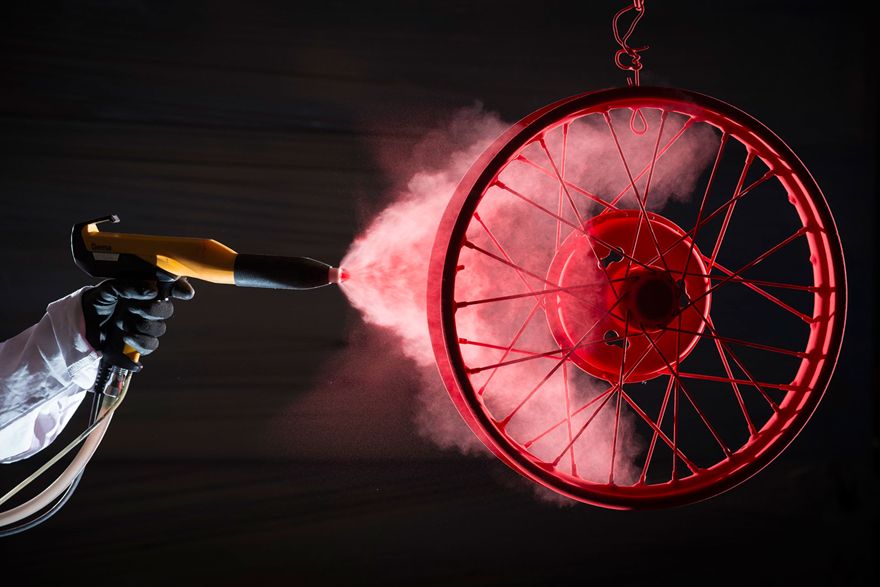

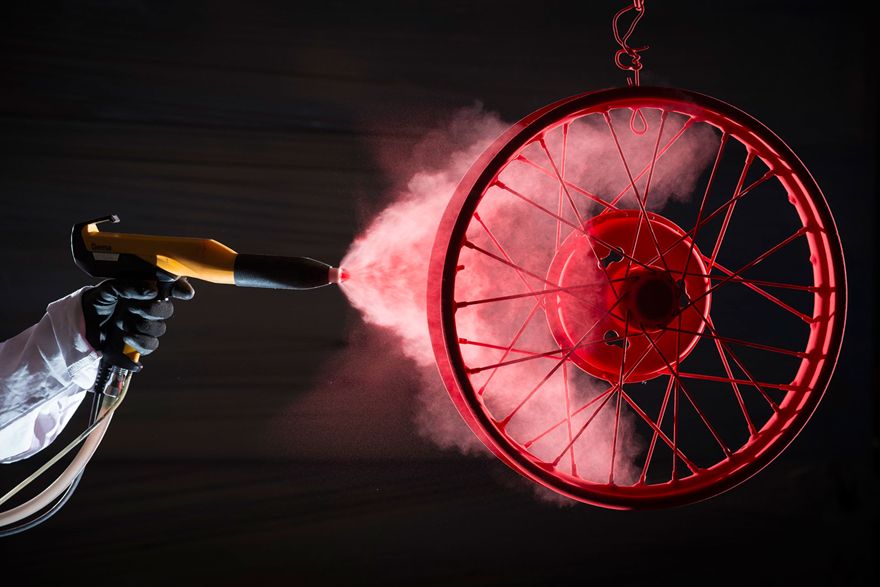

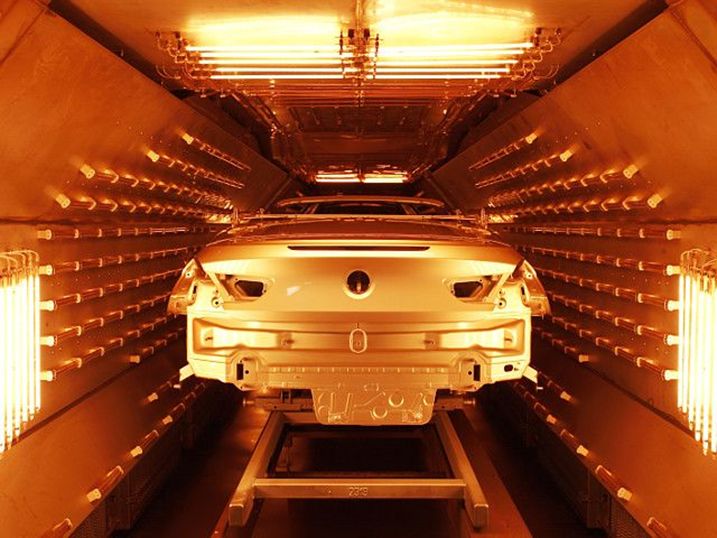

Automotive Industry

Activation and surface preparation before gluing, soldering, or welding. Selective removal of metallic layers and lacquers, as well as selective treatment of welds before painting or passivation.

03

Food Industry

The disinfection and cleaning of production lines and their peripherals, air conditioning, inline cleaning of baking belts, and the handling technologies of drying and tempering furnaces.

04

Medical Industry

Cleaning surfaces from oxides, grease, and organic residues. Sterilisation of a wide range of materials certified for medicine and pharmaceuticals without the need for chemical treatment.

05

Rubber Industry

The maintenance and cleaning of moulds for the production of tires, rubber products, vulcanisation furnaces, and their peripherals.

06

Glass Industry

Cleaning moulds before and after the production of glass products, removing separators, oxides, and organic residues.

07

Batteries

Selective removal of dirt, grease, and oxides before bonding. Removal of cataphoretic layers and preparation of contact surface before encapsulating battery packs.

08

Energy

Large-format cleaning and removing paint from the surfaces of blades, stators, and rotors. Preparation before the painting and passivation of surfaces. Removal of resin insulation.

09

Transport

Selective removal of paints and sprays on the seating surfaces of railway and road systems. Surface treatment before and after welding, passivation, and painting. Large-format removal of painted surfaces and selective removal of functional coatings.

10

Heavy Industry

Preparation before the surface treatment of forming rolls and their maintenance. Large-format removal of protective coatings (PPA, etc.), as well as oxide and process impurities.

11

Semiconductors

Non-contact removal of plated surfaces and the formation of conductive layers and contacts. Cleaning surfaces before creating p-n transition layers.